Industrial Wastewater Treatment

Industrial wastewater treatment covers the mechanisms and processes used to treat waters that have been contaminated in some way by anthropogenic industrial or commercial activities prior to its release into the environment or its re-use.

Most industries produce some wet waste although recent trends in the developed world have been to minimise such production or recycle such waste within the production process. However, many industries remain dependent on processes that produce wastewaters.

Sources of industrial wastewater

Agricultural waste

Breweries

Beer is a fermented beverage with low alcohol content made from various types of grain. Barley predominates, but wheat, maize, and other grains can be used. The production steps include:

• Malt production and handling: grain delivery and cleaning; steeping of the grain in water to start germination; growth of rootlets and development of enzymes (which convert starch into maltose); kilning and polishing of the malt to remove rootlets; storage of the cleaned malt

• Wort production: grinding the malt to grist; mixing grist with water to produce a mash in the mash tun; heating of the mash to activate enzymes; separation of grist residues in the lauter tun to leave a liquid wort; boiling of the wort with hops; separation of the wort from

the trub/hot break (precipitated residues), with the liquid part of the trub being returned

to the lauter tub and the spent hops going to a collection vessel; and cooling of the wort

• Beer production: addition of yeast to cooled wort; fermentation; separation of spent yeast

by filtration, centrifugation or settling; bottling or kegging.

Water consumption for breweries generally ranges 4–8 cubic meter per cubic meter (m3/m3) of beer produced.

Breweries can achieve an effluent discharge of 3–5 m3/m3 of sold beer (exclusive of cooling waters). Untreated effluents typically contain sus-pended solids in the range 10–60 milligrams per liter (mg/l), biochemical oxygen demand (BOD) in the range 1,000–1,500 mg/l, chemical oxygen demand (COD) in the range 1,800–3,000 mg/l,

and nitrogen in the range 30–100 mg/l. Phosphorus can also be present at concentrations of the order of 10–30 mg/l. Effluents from individual process steps are variable. For example, bottle washing produces a large volume of effluent that, however, contains only a minor part of the total organics discharged from the brewery. Effluents from fermentation

and filtering are high in organics and BOD but low in volume, accounting for about 3% of total wastewater volume but 97% of BOD. Effluent pH averages about 7 for the combined effluent but can fluctuate from 3 to 12 depending on the use of acid and alkaline cleaning agents. Effluent temperatures average about 30°C.

Dairy Industry

The dairy industry involves processing raw milk into products such as consumer milk, butter, cheese, yogurt, condensed milk, dried milk (milk powder), and ice cream, using processes such as chilling, pasteurization, and homogenization. Typical by-products include buttermilk, whey, and their derivatives.

Waste Characteristics

Dairy effluents contain dissolved sugars and proteins, fats, and possibly residues of additives. The key parameters are biochemical oxygen demand (BOD), with an average ranging from 0.8 to 2.5 kilograms per metric ton (kg/t) of milk in the untreated effluent; chemical oxygen demand (COD), which is normally about 1.5 times the BOD level; total suspended solids, at 100–1,000 milligrams per liter (mg/l); total dissolved solids: phosphorus (10–100 mg/l), and nitrogen (about 6% of the BOD level). Cream, butter, cheese, and whey production are major sources of BOD in wastewater. The waste load equivalents of specific milk constituents are: 1 kg of milk fat = 3 kg COD; 1 kg of lactose = 1.13 kg COD; and 1 kg protein = 1.36 kg COD. The wastewater may contain pathogens from contaminated materials or production processes. A dairy often generates odors and, in some cases, dust, which need to be controlled. Most of the solid wastes can be processed into other products and byproducts.

Pulp and Paper industry

The pulp and paper industry is one of worlds oldest and core industrial sector. The socio-economic importance of paper has its own value to the country's development as it is directly related to the industrial and economic growth of the country. Paper manufacturing is a highly capital, energy and water intensive industry. It is also a highly polluting process and requires substantial investments in pollution control equipment.

The pulp and paper mill is a major industrial sector utilizing a huge amount of lignocellulosic materials and water during the manufacturing process, and releases chlorinated lignosulphonic acids, chlorinated resin acids, chlorinated phenols and chlorinated hydrocarbons in the effluent. About 500 different chlorinated organic compounds have been identified including chloroform, chlorate, resin acids, chlorinated hydrocarbons, phenols, catechols, guaiacols, furans, dioxins, syringols, vanillins, etc. These compounds are formed as a result of reaction between residual lignin from wood fibres and chlorine/chlorine compounds used for bleaching. Colored compounds and Adsorbable Organic Halogens (AOX) released from pulp and paper mills into the environment poses numerous problems. The wood pulping and production of the paper products generate a considerable amount of pollutants characterized by Biochemical Oxygen Demand (BOD), Chemical Oxygen Demand (COD), Suspended Solids (SS), toxicity, and colour when untreated or poorly treated effluents are discharged to receiving waters. The effluent is toxic to aquatic organisms and exhibits strong mutagenic effects and physiological impairment.

Iron and steel industry

The production of iron from its ores involves powerful reduction reactions in blast furnaces. Cooling waters are inevitably contaminated with products especially ammonia and cyanide. Production of coke from coal in coking plants also requires water cooling and the use of water in by-products separation. Contamination of waste streams includes gasification products such as benzene, naphthalene, anthracene, cyanide, ammonia,phenols, cresols together with a range of more complex organic compounds known collectively as polycyclic aromatic hydrocarbons (PAH).

The conversion of iron or steel into sheet, wire or rods requires hot and cold mechanical transformation stages frequently employing water as a lubricant and coolant. Contaminants include hydraulic oils, tallow and particulate solids. Final treatment of iron and steel products before onward sale into manufacturing includes pickling in strong mineral acid to remove rust and prepare the surface for tin or chromium plating or for other surface treatments such as galvanisation or painting. The two acids commonly used are hydrochloric acid and sulfuric acid. Wastewaters include acidic rinse waters together with waste acid. Although many plants operate acid recovery plants, (particularly those using Hydrochloric acid), where the mineral acid is boiled away from the iron salts, there remains a large volume of highly acid ferrous sulfate or ferrous chloride to be disposed of. Many steel industry wastewaters are contaminated by hydraulic oil also known as soluble oil.

Mines and quarries

The principal waste-waters associated with mines and quarries are slurries of rock particles in water. These arise from rainfall washing exposed surfaces and haul roads and also from rock washing and grading processes. Volumes of water can be very high, especially rainfall related arisings on large sites. Some specialized separation operations, such as coal washing to separate coal from native rock using density gradients, can producewastewater contaminated by fine particulate haematite and surfactants. Oils and hydraulic oils are also common contaminants. Wastewater from metal mines and ore recovery plants are inevitably contaminated by the minerals present in the native rock formations. Following crushing and extraction of the desirable materials, undesirable materials may become contaminated in the wastewater. For metal mines, this can include unwanted metals such as zinc and other materials such as arsenic. Extraction of high value metals such as gold and silver may generate slimes containing very fine particles in where physical removal of contaminantsbecomes particularly difficult.

Food industry

Wastewater generated from agricultural and food operations has distinctive characteristics that set it apart from common municipal wastewater managed by public or private wastewater treatment plants throughout the world: it is biodegradable and nontoxic, but that has high concentrations of biochemical oxygen demand (BOD) and suspended solids (SS).[1] The constituents of food and agriculture wastewater are often complex to predict due to the differences in BOD and pH in effluents from vegetable, fruit, and meat products and due to the seasonal nature of food processing and postharvesting.

Processing of food from raw materials requires large volumes of high grade water. Vegetable washing generates waters with high loads of particulate matter and some dissolved organics. It may also contain surfactants.

Animal slaughter and processing produces very strong organic waste from body fluids, such as blood, and gut contents. This wastewater is frequently contaminated by significant levels of antibiotics and growth hormonesfrom the animals and by a variety of pesticides used to control external parasites. Insecticide residues in fleeces is a particular problem in treating waters generated in wool processing.

Processing food for sale produces wastes generated from cooking which are often rich in plant organic material and may also contain salt, flavourings, colouring material and acids or alkali. Very significant quantities of oil or fats may also be present.

Complex organic chemicals industry

A range of industries manufacture or use complex organic chemicals. These include pesticides, pharmaceuticals, paints and dyes, petro-chemicals, detergents, plastics, paper pollution, etc. Waste waters can be contaminated by feed-stock materials, by-products, product material in soluble or particulate form, washing and cleaning agents, solvents and added value products such as plasticisers.

Nuclear industry

The waste production from the nuclear and radio-chemicals industry is dealt with as Radioactive waste.

Water treatment

Water treatment for the production of drinking water is dealt with elsewhere. (See water purification.) Many industries have a need to treat water to obtain very high quality water for demanding purposes. Water treatment produces organic and mineral sludges from filtration and sedimentation. Ion exchange using natural or synthetic resins removes calcium, magnesium and carbonate ions from water, replacing them withhydrogen and hydroxyl ions. Regeneration of ion exchange columns with strong acids and alkalis produces a wastewater rich in hardness ions which are readily precipitated out, especially when in admixture with otherwastewaters.

Treatment of industrial wastewater

The different types of contamination of wastewater require a variety of strategies to remove the contamination.[2][3]

Solids removal

Most solids can be removed using simple sedimentation techniques with the solids recovered as slurry or sludge. Very fine solids and solids with densities close to the density of water pose special problems. In such casefiltration or ultrafiltration may be required. Although, flocculation may be used, using alum salts or the addition of polyelectrolytes.

Oils and grease removal

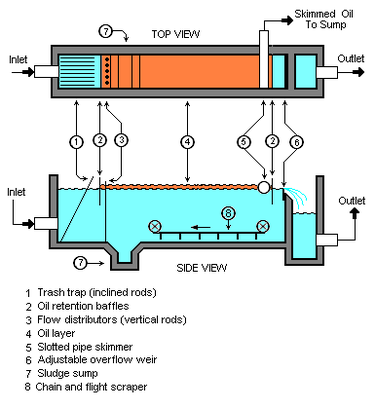

A typical API oil-water separator used in many industries

Many oils can be recovered from open water surfaces by skimming devices. Considered a dependable and cheap way to remove oil, grease and other hydrocarbons from water, oil skimmers can sometimes achieve the desired level of water purity. At other times, skimming is also a cost-efficient method to remove most of the oil before using membrane filters and chemical processes. Skimmers will prevent filters from blinding prematurely and keep chemical costs down because there is less oil to process.

Because grease skimming involves higher viscosity hydrocarbons, skimmers must be equipped with heaters powerful enough to keep grease fluid for discharge. If floating grease forms into solid clumps or mats, a spray bar, aerator or mechanical apparatus can be used to facilitate removal.[4]

However, hydraulic oils and the majority of oils that have degraded to any extent will also have a soluble or emulsified component that will require further treatment to eliminate. Dissolving or emulsifying oil using surfactants or solvents usually exacerbates the problem rather than solving it, producing wastewater that is more difficult to treat.

The wastewaters from large-scale industries such as oil refineries, petrochemical plants, chemical plants, and natural gas processing plants commonly contain gross amounts of oil and suspended solids. Those industries use a device known as an API oil-water separator which is designed to separate the oil and suspended solids from their wastewater effluents. The name is derived from the fact that such separators are designed according to standards published by the American Petroleum Institute (API).[3][5]

The API separator is a gravity separation device designed by using Stokes Law to define the rise velocity of oil droplets based on their density and size. The design is based on the specific gravity difference between the oil and the wastewater because that difference is much smaller than the specific gravity difference between the suspended solids and water. The suspended solids settles to the bottom of the separator as a sediment layer, the oil rises to top of the separator and the cleansed wastewater is the middle layer between the oil layer and the solids.[3]

Typically, the oil layer is skimmed off and subsequently re-processed or disposed of, and the bottom sediment layer is removed by a chain and flight scraper (or similar device) and a sludge pump. The water layer is sent to further treatment consisting usually of a Electroflotation module for additional removal of any residual oil and then to some type of biological treatment unit for removal of undesirable dissolved chemical compounds.

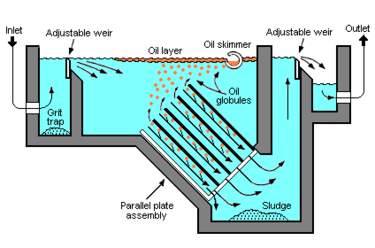

A typical parallel plate separator

Parallel plate separators[6] are similar to API separators but they include tilted parallel plate assemblies (also known as parallel packs). The parallel plates provide more surface for suspended oil droplets to coalesce into larger globules. Such separators still depend upon the specific gravity between the suspended oil and the water. However, the parallel plates enhance the degree of oil-water separation. The result is that a parallel plate separator requires significantly less space than a conventional API separator to achieve the same degree of separation.

Removal of biodegradable organics

Biodegradable organic material of plant or animal origin is usually possible to treat using extended conventional wastewater treatment processes such as activated sludge or trickling filter.[2][3] Problems can arise if the wastewater is excessively diluted with washing water or is highly concentrated such as neat blood or milk. The presence of cleaning agents, disinfectants, pesticides, or antibiotics can have detrimental impacts on treatment processes.

Activated sludge process

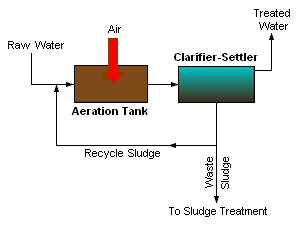

A generalized, schematic diagram of an activated sludge process.

Activated sludge is a biochemical process for treating sewage and industrial wastewater that uses air (or oxygen) and microorganisms to biologically oxidize organic pollutants, producing a waste sludge (or floc) containing the oxidized material. In general, an activated sludge process includes:

An aeration tank where air (or oxygen) is injected and thoroughly mixed into the wastewater.

A settling tank (usually referred to as a "clarifier" or "settler") to allow the waste sludge to settle. Part of the waste sludge is recycled to the aeration tank and the remaining waste sludge is removed for further treatment and ultimate disposal.

Trickling filter process

A schematic cross-section of the contact face of the bed media in a trickling filter

A trickling filter consists of a bed of rocks,gravel, slag, peat moss, or plastic media over which wastewater flows downward and contacts a layer (or film) of microbial slime covering the bed media. Aerobic conditions are maintained by forced air flowing through the bed or by natural convection of air. The process involves adsorption of organic compounds in the wastewater by the microbial slime layer, diffusion of air into the slime layer to provide the oxygen required for the biochemical oxidation of the organic compounds. The end products include carbon dioxide gas, water and other products of the oxidation. As the slime layer thickens, it becomes difficult for the air to penetrate the layer and an inner anaerobic layer is formed.

The components of a complete trickling filter system are: fundamental components:

- A bed of filter medium upon which a layer of microbial slime is promoted and developed.

- An enclosure or a container which houses the bed of filter medium.

- A system for distributing the flow of wastewater over the filter medium.

- A system for removing and disposing of any sludge from the treated effluent.

The treatment of sewage or other wastewater with trickling filters is among the oldest and most well characterized treatment technologies.

A trickling filter is also often called a trickle filter, trickling biofilter, biofilter, biological filter or biological trickling filter.

Treatment of other organics

Synthetic organic materials including solvents, paints, pharmaceuticals, pesticides, coking products and so forth can be very difficult to treat. Treatment methods are often specific to the material being treated. Methods include Advanced Oxidation Processing, distillation, adsorption, vitrification, incineration, chemical immobilisation or landfill disposal. Some materials such as some detergents may be capable of biological degradation and in such cases, a modified form of wastewater treatment can be used.

Treatment of acids and alkalis

Acids and alkalis can usually be neutralised under controlled conditions. Neutralisation frequently produces a precipitate that will require treatment as a solid residue that may also be toxic. In some cases, gasses may be evolved requiring treatment for the gas stream. Some other forms of treatment are usually required following neutralisation.

Waste streams rich in hardness ions as from de-ionisation processes can readily lose the hardness ions in a buildup of precipitated calcium and magnesium salts. This precipitation process can cause severe furring of pipes and can, in extreme cases, cause the blockage of disposal pipes. A 1 metre diameter industrial marine discharge pipe serving a major chemicals complex was blocked by such salts in the 1970s. Treatment is by concentration of de-ionisation waste waters and disposal to landfill or by careful pH management of the released wastewater.

Treatment of toxic materials

Toxic materials including many organic materials, metals (such as zinc, silver, cadmium, thallium, etc.) acids, alkalis, non-metallic elements (such as arsenic or selenium) are generally resistant to biological processes unless very dilute. Metals can often be precipitated out by changing the pH or by treatment with other chemicals. Many, however, are resistant to treatment or mitigation and may require concentration followed by landfilling or recycling. Dissolved organics can be incinerated within the wastewater by Advanced Oxidation Processes.

References

^ European Environment Agency. Copenhagen, Denmark. "Indicator: Biochemical oxygen demand in rivers (2001)."

^ a b Tchobanoglous, G., Burton, F.L., and Stensel, H.D. (2003). Wastewater Engineering (Treatment Disposal Reuse) / Metcalf & Eddy, Inc. (4th ed.). McGraw-Hill Book Company. ISBN 0-07-041878-0.

^ a b c d Beychok, Milton R. (1967). Aqueous Wastes from Petroleum and Petrochemical Plants (1st ed.). John Wiley & Sons. LCCN 67019834.

^ Water and Wastewater News, May 2004 (http://wwn-online.com/articles/50898/)

^ American Petroleum Institute (API) (February 1990). Management of Water Discharges: Design and Operations of Oil-Water Separators (1st ed.). American Petroleum Institute.

^ a b Beychok, Milton R. (December 1971). "Wastewater treatment". Hydrocarbon Processing: 109–112. ISSN 0818-8190.

Resources

This article has been created using materials from Wikipedia - Click here to read the related Wikipedia article on Industrial Wastewater Treatment.