Reduction of Sludge Production in Wastewater Treatment Plants

Sludge Production

The volume of sludge produced in a WWTP is only about 1% (dewatered sludge is 0.5‰) of the volume of influent wastewater to be treated. To manage WWTPs effectively and efficiently, it is absolutely necessary to extract waste sludge, including inert solids and excess biomass, in order to prevent their accumulation within the system.

Wastewater Handling Units

In the wastewater handling units in a WWTP the types of sludge produced are:

- primary sludge – produced by settleable solids removed from raw wastewater in primary settling; characterised by high putrescibility and good dewaterability when compared to biological sludge; TS content in primary sludge is in the range 2-7% (Turovskiy and Mathai, 2006);

- secondary sludge (also called biological sludge) – produced by biological processes such as activated sludge or biofilm systems; contains microorganisms grown on biodegradable matter (either soluble or particulate), endogenous residue and inert solids not removed in the primary settling (where a primary settler is present) or entering with the raw wastewater (where no primary settler is present); TS content in secondary sludge is in the range 0.5-1.5% (Turovskiy and Mathai, 2006);

- chemical sludge – produced by precipitation of specific substances (i.e. phosphorus) or suspended solids.

Sludge Handling Units

In the sludge handling units, a combination of any two or three of the above types is introduced.

During the biological treatment of wastewater, in addition to cell biomass, a large amount of non-biodegradable (inert) solids in particulate form, incoming with the influent raw wastewater, contributes significantly to sludge production. The presence of inert organic solids in sludge is due either to their presence in the influentwastewater (e.g. hairs, fibers, etc…), to the endogenous residue produced in microbial decay or to protozoan activity, which may not fully degrade the bacterial cell walls leaving behind inert material (van Loosdrecht and Henze, 1999). Therefore it is very important to know the composition of sludge in order to understand and approximate the potential efficiency of a sludge reduction technique. When a very high sludge reduction is desired, the conversion of a significant part of refractory particulate organic material into a biodegradable fraction is needed.

Principles of Sludge Reduction Techniques

The cost for treatment + disposal of sludge in European countries has been estimated to reach, on average, approximately 500 € per tonne of dry mass, according to the type of treatment and disposal, but a further increase is expected in the near future. As a consequence of the sludge production which is increasing, whereas disposal routes are narrowing, is a progressive further rising in costs. There are two aims with regard to sludge:

- the recovery of materials or energy from sludge, if sludge is considered a resource;

- the reduction of the amount of sludge produced, if sludge is considered waste.

For many producers, there are not enough economic advantages to make beneficial reuse of sludge an attractive investment. Even though a sludge-zero process remains the utopia in sludge management, a more realistic and feasible practice is to continue to reduce the volume and mass of sludge produced. The current approach to sludgereduction addresses the two following aspects:

1) reduction of volume of wet sludge;

2) reduction of dry mass of sludge.

The increase of the solid content in sludge by dewatering significantly reduces the volume of wet sludge for disposal.

The reduction of dry mass of sludge leads to the reduction of solid content and volume and this strategy should be favoured, because it allows the immediate reduction ofsludge dry mass during its production in the biological treatment stage.

Many studies have been produced since the ‘90s on alternative technologies for direct on-site reduction of sludge production (as dry mass and not only in volume). The proposed methods are based on physical, mechanical, chemical, thermal and biological treatments. Most of them are aimed at solids solubilisation and disintegration of bacterial cells in sludge, with the objectives of:

- reducing sludge production directly in the wastewater handling units;

- reducing sludge mass in the sludge handling units and simultaneously improving biogas production in anaerobic digestion or, in some cases, dewaterability;

- (in few cases) producing an additional carbon source to support denitrification and phosphorous removal in the wastewater handling units.

Mechanisms in Sludge Reduction Techniques

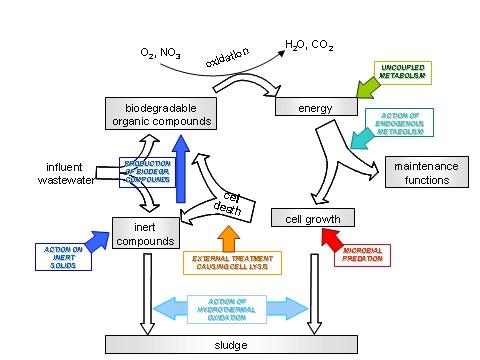

The various mechanisms exploited in the sludge reduction techniques are identified and schematically indicated in the figure.

Cell lysis and cryptic growth

The term “cryptic growth” indicates the reutilisation of intracellular compounds (both carbonaceous compounds and nutrients) released from cell lysis, for the growth of viable cells of the same population. Some sludge reduction techniques cause cell lysis with the consequent solubilisation of cellular constituents, which become substrate available for further biodegradation. The cryptic growth process is thus induced which results in an overall reduction of sludge production.

Uncoupled metabolism

The term “uncoupling” defines the inability of oxidative phosphorylation to generate the maximum theoretical quantity of metabolic energy in the form of ATP. The uncoupled metabolism increases the discrepancy in the energy level between catabolism and anabolism, limiting the energy available for anabolism. As a consequence, bacteria first satisfy their maintenance functions before spending energy on growth and consequently there is less energy available for the synthesis of new cells. The biomass yield is thus reduced and the sludge production decreases.

Endogenous metabolism

The concept of the endogenous metabolism describes the observation that storage compounds are used for maintenance purposes when the external substrate is completely depleted. In other words, endogenous metabolism should be defined as a state when no net growth is possible, but cells consume energy to remain viable. By increasing energy requirements for non-growth activities, in particular maintenance functions, the amount of energy available for the growth of biomass decreases. Therefore a significant reduction of sludge production can be achieved by maximising the energy used for maintenance requirements rather than for cellular synthesis.

Microbial predation

Bacteria are a food source for higher organisms, such as protozoa and metazoa. When one organism eats another the total amount of biomass decreases and the transfer to a higher trophic level of the food chain occurs. In this way part of the biomass and the potential energy is lost as heat and excretory products, which causes a reduced growth of biomass and lower sludge production.

Biodegradability increase in inert solids

A further mechanism, which is linked to biodegradability increase of inert solids, can be considered, even though it can not be considered a separate mechanism because it takes place in combination with other mechanisms. For example, ozonation is expected to be a strong oxidant on all sludge components: whether cellular biomass or inert compounds. This treatment on cellular biomass induces cell lysis-cryptic growth, while its effect on inert solids is an enhancement of solubilisation with a potential increase of biodegradability of the compounds released.

Hydrothermal oxidation

Once produced, the sludge can undergo hydrothermal oxidation processes to reduce the amount requiring disposal. The sludge mineralisation using oxygen can be achieved at high temperature (>850°C) in the gaseous phase (incineration) or at a relatively low temperature (in the range 150-320°C or >374°C) in the liquid phase: water (subcritical or supercritical) is used as a reaction medium. Two hydrothermal oxidation processes are available: (1) subcritical water oxidation, including wet air oxidation; (2) supercritical water oxidation.

Technologies

These 5 mechanisms are exploited in various technologies aimed to the reduction of sludge production. The technologies can be integrated in the wastewater handling units or in the sludge handling units. From an economic point of view, some techniques are more advantageous when applied to sludge with high solid content, such as return sludge or thickened sludge.

When the sludge reduction technique is applied to the return sludge, the treatment produces biodegradable carbonaceous matter supporting denitrification in activatedsludge stages. When it is integrated in the sludge handling units, improvements in biogas production and sludge stabilisation in anaerobic digesters are obtained. An additional benefit can be the reduction of foam caused by filamentous bacteria in biological reactors.

Many of the techniques for sludge reduction are suitable for implementation in the wastewater handling units or in the sludge handling units of an existing WWTP, often by simply retrofitting the specific additional equipment. The extent to which the most appropriate technique for sludge reduction is chosen will depend upon many factors including local conditions, existing configurations of the treatment facility, the number and skill of the operators, the attitude of the water companies, the involvement of suppliers of the technology and equipment in question.

The techniques proposed for the on-site sludge reduction in a WWTP lead to additional costs for investment and operations: this aspect requires a detailed evaluation of the economical advantages by comparing the performance of the selected technique (and the effective reduction in dry mass of sludge) with the cost for the final disposal of sludge.

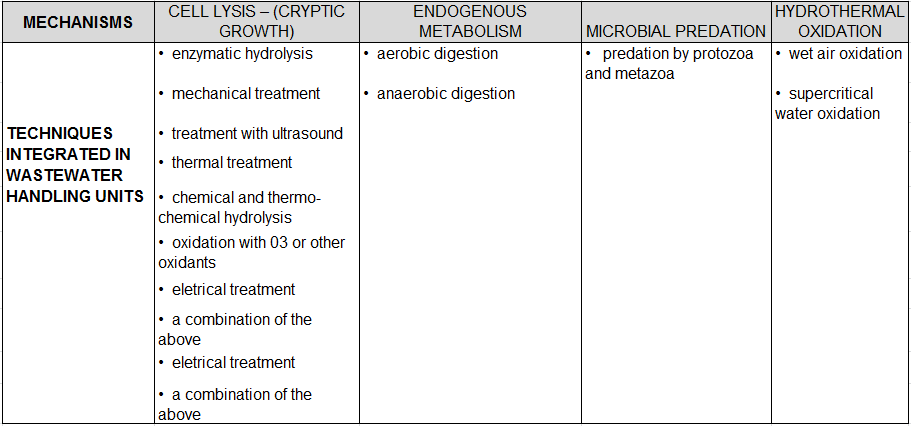

Technologies in the Wastewater Handling Units

(known also as the water line)

The objective is to reduce sludge production directly in the wastewater treatment units instead of realising post-treatments of sludge after its production. In the table the main technologies which activate each mechanism are indicated.

Technologies in the Sludge Handling Units

(known also as the sludge line)

The reduction of sludge mass occurs after its production in the wastewater handling units. In the table the main technologies which activate each mechanism are indicated.

Resources

The material in this article is covered in the book, Sludge Reduction Technologies in Wastewater Treatment Plants, published by IWA Publishing.

Sludge Reduction Technologies in Wastewater Treatment Plants is a review of the sludge reduction techniques integrated in wastewater treatment plants with detailed chapters on the most promising and most widespread techniques. The aim of the book is to update the international community on the current status of knowledge and techniques in the field of sludge reduction. It will provide a comprehensive understanding of the following issues in sludge reduction:

- principles of sludge reduction techniques;

- process configurations;

- potential performance;

- advantages and drawbacks;

- economics and energy consumption.

This book is essential reading for managers and technical staff of wastewater treatment plants as well as graduate students and post-graduate specialists.

References

Paola Foladori, Gianni Andreottola, Giuliano Ziglio, Sludge Reduction Technologies in Wastewater Treatment Plants, IWA Publishing: 2010, ISBN: 9781843392781

Turovskiy I.S., Mathai P.K. (2006) Wastewater sludge processing. Wiley-Interscience. John Wiley & Sons, Inc., Hoboken, New Jersey.

van Loosdrecht M.C.M., Henze M. (1999) Maintenance, endogenous respiration, lysis, decay and predation. Water Science and Technology, 39(1): 107-117.

Related Publications

Applications of Activated Sludge Models - D. Brdjanovic, S.C.F Meijer, C.M. Lopez-Vazquez, C.M. Hooijmans, M.C.M. van Loosdrecht

Publication Date: Sep 2014 - ISBN - 9781780404639

Evolution of Sanitation and Wastewater Technologies through the Centuries - Andreas N. Angelakis, Peter A. Wilderer and Joan Bray Rose

Publication Date: Mar 2014 - ISBN - 9781780404844

Experimental Methods in Wastewater Treatment - M.C.M. van Loosdrecht, J. Keller, P.H. Nielsen, C.M. Lopez-Vazquez and D. Brdjanovic

Publication Date: Feb 2014 - ISBN - 9781780404745